08

Mar

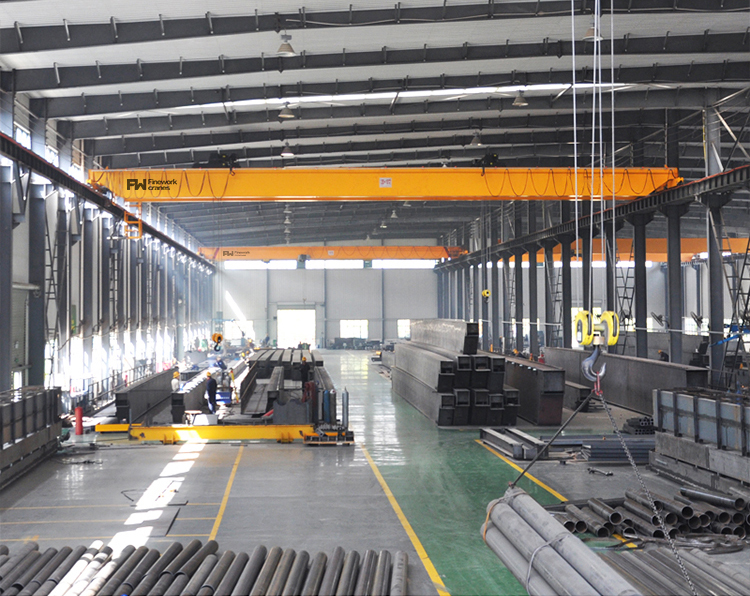

In a significant milestone for international trade and industrial collaboration, two sets of CXTS7T single girder overhead cranes with a 15-meter span and 6.5-meter lifting height have been successfully delivered to a client in Peru. These cranes, designed and manufactured with precision, are set to enhance the material handling capabilities of the client’s operations. This delivery underscores the growing demand for high-quality lifting equipment in South America and highlights the expertise of the manufacturer in meeting global standards.

.jpg)

Ⅰ. Product Description, Features, and Model

The CXTS7T single girder overhead crane is a state-of-the-art lifting solution designed for efficiency, durability, and ease of operation. This crane model is particularly suited for medium-duty lifting tasks in industries such as manufacturing, warehousing, and logistics.

Key Features:

1. Single Girder Design: The crane features a single girder steel structure, which provides a lightweight yet robust framework, making it ideal for facilities with space constraints.

2. 15-Meter Span: With a span of 15 meters, the crane covers a wide working area, ensuring maximum flexibility in load handling.

3. 6.5-Meter Lifting Height: The crane offers a lifting height of 6.5 meters, allowing it to handle tall loads and operate in facilities with high ceilings.

4. Steel Structure: Built with high-grade steel, the crane ensures exceptional durability and resistance to wear and tear, even in demanding industrial environments.

5. Electric Hoist: Equipped with a reliable electric hoist, the crane provides smooth and precise lifting operations. The hoist is designed for medium-duty applications, with a lifting capacity of up to 7 tons.

6. User-Friendly Controls: The crane is operated via a pendant control system, allowing operators to manage lifting and movement with ease and precision.

7. Safety Features: The CXTS7T model includes essential safety mechanisms such as overload protection, emergency stop buttons, and limit switches to ensure safe operation.

Applications:

The CXTS7T single girder overhead crane is widely used in various industries, including:

1. Manufacturing: For moving raw materials, machinery, and finished products.

2. Warehousing: For loading and unloading goods, stacking pallets, and organizing inventory.

3. Logistics: For handling heavy loads in distribution centers.

4. Construction: For transporting building materials and equipment.

This crane model is particularly valued for its versatility, cost-effectiveness, and low maintenance requirements, making it a popular choice for businesses looking to optimize their material-handling processes.

Ⅱ. Negotiation and Communication Process with Customers

The successful delivery of these cranes to Peru was the result of meticulous planning, clear communication, and a customer-centric approach. The process began when the Peruvian client expressed interest in upgrading their material-handling equipment to improve efficiency and safety in their operations.

1. Initial Consultation:

Our sales team conducted a detailed consultation to understand the client’s specific requirements, including the desired span, lifting height, and load capacity. Based on this information, the team recommended the CXTS7T single girder overhead crane as the ideal solution.

2. Technical Discussions:

Engineers from both sides engaged in technical discussions to finalize the crane’s specifications. The client’s team provided insights into their facility’s layout and operational challenges, while our engineers offered expert advice on customization options, such as the 15-meter span and 6.5-meter lifting height.

3. Quotation and Agreement:

After several rounds of negotiations, Finework Salesman provided a comprehensive quotation, including the cost of the cranes, customization, packaging, and transportation. The client appreciated the transparency and competitive pricing, leading to the signing of the agreement.

4. Ongoing Communication:

Throughout the manufacturing process, we maintained regular communication with the client, providing updates on production progress and addressing any concerns. This open line of communication ensured that the client was fully informed and confident in the project’s progress.

.jpg)

Ⅲ. Packaging and Transportation

To ensure the safe delivery of the cranes to Peru, we implemented a robust packaging and transportation plan. The cranes were disassembled into major components, including the girder, end trucks, hoist, and electrical systems. Each component was carefully packed using durable materials to prevent damage during transit.

The packaged components were then loaded into shipping containers and transported via sea freight. Our Saleperson collaborated with a reliable logistics partner to handle customs clearance and ensure timely delivery. Upon arrival in Peru, the cranes were transported to the client’s facility, where they were reassembled and installed by a team of skilled technicians.

.jpg)

.jpg)

Ⅳ. Customer Feedback

The client in Peru expressed high satisfaction with the CXTS7T single girder overhead cranes. They praised the cranes for their robust construction, smooth operation, and ability to meet their specific requirements. The client also commended Finework for their professionalism, timely delivery, and excellent after-sales support.

Client Statement:

“The CXTS7T cranes have significantly improved our material-handling efficiency. The 15-meter span and 6.5-meter lifting height are perfect for our facility, and the crane’s performance has exceeded our expectations. We look forward to future collaborations with the Finework cranes.”

English

English

Spanish

Spanish

Russian

Russian